Circular Bulk Bag

Circular bulk bags are an industrial packaging made of durable, tear-resistant, heavy-duty woven polypropylene. These bags can safely carry weights from 500 kg to 2000 kg. Circular bulk bags maintain their integrity and functionality even in extreme conditions or after multiple handling. They are widely used in agriculture, construction and mining industries for the storage and transportation of grains, chemicals and minerals. These bags have a round base and cylindrical walls to hold large amounts of material. A soft frame at the bottom maintains the shape of the bag and ensures that the contents are evenly distributed. Extended handles allow for easy hanging and transportation by forklifts and cranes. We offer a variety of sizes and weight capacities to meet the needs and characteristics of specific items.

Features

- Improving DurabilityCircular bulk bags feature a seamless design. Vertical seams tend to concentrate stress, reducing durability and shortening bag lifespan. Studies show that seamless bulk bags last on average 30% longer than seamed versions. This extended lifespan reduces the need for frequent replacements. The improved durability also lowers replacement frequency, cutting long-term costs. It is estimated that circular bulk bags can save users up to 25% in packaging expenses.

- Enhancing Material EfficiencyTraditional multi-panel FIBCs require cutting and joining multiple parts during manufacturing, resulting in greater raw material waste. Research indicates that circular bulk bags made with continuous fabric can reduce production waste by up to 20%. Additionally, by minimizing cutting and connecting steps, production efficiency improves, reducing labor and energy consumption. This design is estimated to cut manufacturing costs by approximately 15%.

- Robustness and DurabilityThe high-strength weaving technology used in circular bulk bags ensures reliable performance under heavy loads. Test data show these bags can safely carry weights from 500 kg to 2000 kg. Even under extreme conditions or after repeated use, they maintain structural integrity and functionality. Their durability also means less maintenance and fewer replacements, leading to lower long-term operational costs. It is estimated that high-strength circular bulk bags can reduce maintenance expenses by up to 30%. Although the initial investment may be higher, their longevity and low maintenance requirements make them cost-effective. Overall calculations indicate that the total cost of ownership is about 25% lower than that of traditional bags.

Specifications

| Product Name | FIBC pp big Bag |

| Fabric Material | PP (Polypropylene) |

| Fabric Color | Milky white/Black/Beige/Customized color/UV add |

| Fabric Ctructure | Tubular/U-panel/baffle/rectangular shape |

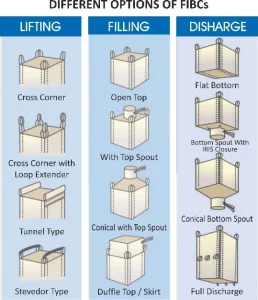

| Top Option (Filling) | Open/Filling spout/ Skirt |

| Loop Option (Lifting) | Side-Seam Loop/Cross Corner Loop |

| Loop Color | blue/white/ black/beige/pink/customized color |

| Safety Factor | 3:1/5:1 |

| Usage | Mining/Chemicals/Agricultural products/Cement/Sand |

| Bottom Option (Discharge) | Flat Bottom/With Spout |

| Fabric GSM | 80-200 gsm |

| Fabric Mesh | 80 to 200 gsm |

| Fabric Denier | 700D-1800D or Customized |

| Bag Size | 90*90*110/95*95*110/100*100*120cm/Custom Size Accepted |

| Capacity | 500kg to 3000 kg or customized |

| Bag Sewing | Flatlock/Lockstitch/Heat Sealing/Overlock/Reinforced |

| Optional Processing | Film covering( coating)/Inner PE bag/Printing/Leakage Proof |

| Optional Characteristics | Breathable/airy/anti-static/conductive/UV/stabilization/reinforcement/dust-proof/moisture-proof |

| Packaging | In bales/ Palletization |

Packaging