Multiwall Paper Bags

A multi-layer paper bag is a packaging bag made of multiple layers of kraft paper or other types of paper bonded together through a special process. This type of paper bag has high strength and durability and is commonly used to package and transport various bulk solid materials, such as chemical products, food raw materials, and animal feed. Compared with traditional plastic woven bags, multi-layer paper bags usually cost less. A medium-sized multi-layer paper bag may be sold for 0.5 yuan per piece, while a plastic woven bag of the same size may cost 1 yuan. In addition, a typical multi-layer paper bag can withstand a weight of up to 50 kilograms, so multi-layer paper bags are not easy to damage goods during transportation and storage, which reduces the risk of cargo loss due to improper packaging. In addition, multi-layer paper bags can be naturally degraded through composting after use, which means that they will not accumulate in the environment like plastics and cause long-term pollution. The environmental performance of multi-layer paper bags makes them the preferred choice of the public.

Features

- Economic Benefits

Compared with plastic woven bags or other types of packaging materials, multi-layer paper bags generally have lower costs. For example, a medium-sized multi-layer paper bag may be sold for 0.5 yuan/piece, while a plastic woven bag of the same size may cost 1 yuan/piece. In addition to the low material price, due to its sturdy structure, multi-layer paper bags are not easy to damage goods during transportation and storage. This reduces the risk of cargo loss and claims due to improper packaging. For example, if a company reduces the cargo damage rate by 1% each year by using multi-layer paper bags, it may avoid a loss of 100,000 yuan for a company with annual sales of 10 million yuan. - Environmental Sustainability

Multi-layer paper bags are mainly made of kraft paper, which is a renewable resource. In contrast, traditional plastic packaging is usually derived from non-renewable petroleum products. Using renewable materials can reduce dependence on fossil fuels, thereby reducing greenhouse gas emissions. In addition, multi-layer paper bags can be naturally degraded by composting after use, which means that they will not accumulate in the environment like plastics, causing long-term pollution. For example, a typical multi-layer paper bag may take several months to several years to completely decompose, while plastic may take hundreds of years. Finally, multi-layer paper bags can be recycled and reused, which reduces the demand for raw materials and the pressure on landfills. During the recycling process, paper can be re-pulped and used to produce new paper products such as cardboard, toilet paper, etc. - Durability

Despite their low price, multi-layer paper bags are not inferior in quality. They are made of multiple layers of kraft paper, which have good tear resistance and load-bearing capacity. For example, a typical multi-layer paper bag can withstand up to 50 kilograms, which is enough for most non-hazardous goods packaging. - High tear resistance

Multi-layer paper bags are usually made of three or more layers of kraft paper, and each layer adds to the overall thickness and strength. For example, a five-layer multi-layer paper bag may have up to 50% higher tear resistance than a single-layer paper bag. This feature is essential for protecting fragile or valuable items during transportation and handling.

Specifications

| Paper Material | Paper( Kraft paper/bleached white paper) |

| Features Selection | Biodegradable/ recyclable/eco-friendly/Waterproof/moisture proof/leak proof |

| Paper Color | Brown/ white/ customized color |

| Paper GSM | 40-150gsm customized |

| Paper Layers | 1/2/3/4/5/6 layers |

| Bag Width | 30-70cm customized |

| Bag Length | 40-120cm customized |

| Capacity | 2kg, 5kg, 10kg, 20kg, 25kg,50kg or customized |

| BagTop | Cold cut/ zigzag cut/D cut/hemmed top/handle pasted |

| Bag Bottom Seal | Single line sewing/ double lines sewing/ easy open/heat seal tape/ block bottom/ valve |

| Coating option | PE film/9-40 gsm/( inside/outside) |

| Lamination option | PP woven fabric |

| Printing | Offset printing Max 5 colors /Flexo printing Max 10 colors |

| Bag Shape | Tubular/ M gussets/ Block bottom/Valves |

| Optional Processing | PE liner inside/ anti slip/Micro perforation/ventilation holes |

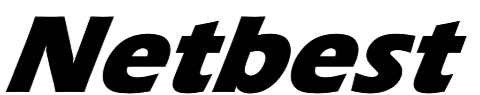

| Usage | Flour,feed, fertilizer,chemical, resin, powder products,charcoal |

| Packaging | In bales/ Palletization with cardboard |